Page 6 - catalog Medhim

P. 6

Zubchaninovskoe sh. 128/2, Samara, Russia, 443109

Tel/fax: +7 (846) 931-00-66/69/90

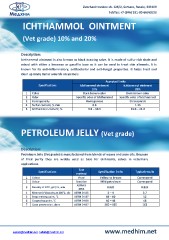

ICHTHAMMOL OINTMENT

(Vet grade) 10% and 20%

Description:

Ichthammol ointment is also known as black drawing salve. It is made of sulfur-rich shale and

mixed with either a beeswax or paraffin base so it can be used to treat skin aliments. It is

known for its anti-inflammatory, antibacterial and anti-fungal properties. It helps treat and

clear up many minor wounds on animals.

Accepted limits

Specifications Ichthammol ointment Ichthammol ointment

1 Color 10% 20%

2 Odor

3 Homogeneity Dark-brown color Dark-brown color

4 Sulfur content, % min

5 Ichthammol content, % Specific odor of ichthammol Specific odor of ichthammol

Homogenous Corresponds

0.6 1.15

9.5 – 10.5 19.0 – 21.0

PETROLEUM JELLY (Vet grade)

Description:

Petroleum Jelly (Vet grade) is manufactured from blends of waxes and pure oils. Because

of their purity they are widely used as base for ointments, salves in veterinary

applications.

Specifications Test Specification limits Typical results

method

Yellow to brown Correspond

1 Colour Visual Mild petroleum Correspond

2 Odour Sensitive 0.820 0.824

3 Density at 20°C, gm/ml, min ASTM D 3–4 3.7

4052 48 – 60 52

46 – 48 48

4 Kinematic Viscosity at 100°C, cSt ASTM D 445 145 – 165 163

5 Drop melting point, °C ASTM D 127

6 Congealing point, °C ASTM D 938

7 Cone penetration, dmm ASTM D 937

export@medhim.net, rudnik@medhim.net www.medhim.net